Cosmetic Crown & Bridges

Dental crown

A dental crown, also known as a dental cap, is a type of dental restoration that covers or encases a damaged or weakened tooth. It is designed to restore the shape, size, strength, and appearance of the tooth, while providing protection and support.

Dental crowns are commonly recommended when a tooth has a large cavity that compromises its structural integrity and long-term health. They are designed to cover the entire tooth, providing protection and support. The crown is bonded to the tooth using dental cement, creating a strong and durable restoration.

Why Do I Need a Crown?

- There are several reasons why you may need a dental crown. Some common reasons include

- Fractured or broken tooth: If a tooth is severely fractured or broken, a crown can help restore its shape, strength, and function. The crown holds the tooth together and prevents further damage.

- Root canal treatment: After undergoing a root canal procedure, the tooth becomes more fragile and prone to fracture. A crown is often placed over the treated tooth to provide strength and protection.

- Cosmetic reasons: Crowns can also be used for cosmetic purposes to improve the appearance of a tooth. They can cover teeth that are discolored, misshapen, or have other aesthetic concerns.

- Dental bridge support: When replacing a missing tooth with a dental bridge, the adjacent teeth that support the bridge may need to be crowned to provide stability and support.

If you are experiencing any dental issues that may require a crown, it is best to consult with a dentist. They will evaluate your oral health, discuss treatment options, and determine if a crown is the appropriate solution for your specific situation.

Dental crown procedure

Dental bridge

A dental bridge is a dental restoration used to replace one or more missing teeth by bridging the gap between adjacent teeth. It consists of artificial teeth, called pontics, that are anchored in place by dental crowns or abutments on the neighboring teeth.

Type of bridge

There are several types of dental bridges commonly used to replace missing teeth. The type of bridge recommended for you will depend on various factors, including the location of the missing tooth or teeth, the health of the adjacent teeth, and your personal preferences. Here are the main types of dental bridges

Metal alloy

Metal alloy bridges, also known as metal-supported bridges or traditional bridges, are a type of dental bridge that incorporates metal alloys as the primary framework or substructure. These bridges are known for their strength, durability, and reliable performance.

The metal alloy used in these bridges is typically a combination of various metals, such as gold, silver, palladium, or non-precious metals like nickel or chromium. The choice of metal alloy depends on factors like cost, aesthetics, and the specific requirements of the patient.

Cantilever bridges

Cantilever bridges are a type of dental bridge used to replace a missing tooth when there is only one natural tooth adjacent to the gap. Unlike traditional bridges that are supported by two abutment teeth on either side of the gap, a cantilever bridge is supported by a single abutment tooth.

Maryland bonded bridges

Maryland bonded bridges, also known as resin-bonded bridges or Maryland bridges, are a type of dental bridge used to replace a missing tooth.are made of plastic teeth and gums supported by a metal framework. These bridges are known for their conservative approach and minimal alteration of the adjacent teeth. Material used for the crowns & bridges and Types of dental crowns Numerous dental crown options are available, each tailored to individual preferences and specific oral health requirements.

Cantilever bridges

Cantilever bridges are a type of dental bridge used to replace a missing tooth when there is only one natural tooth adjacent to the gap. Unlike traditional bridges that are supported by two abutment teeth on either side of the gap, a cantilever bridge is supported by a single abutment tooth.

Maryland bonded bridges

Maryland bonded bridges, also known as resin-bonded bridges or Maryland bridges, are a type of dental bridge used to replace a missing tooth.are made of plastic teeth and gums supported by a metal framework. These bridges are known for their conservative approach and minimal alteration of the adjacent teeth.

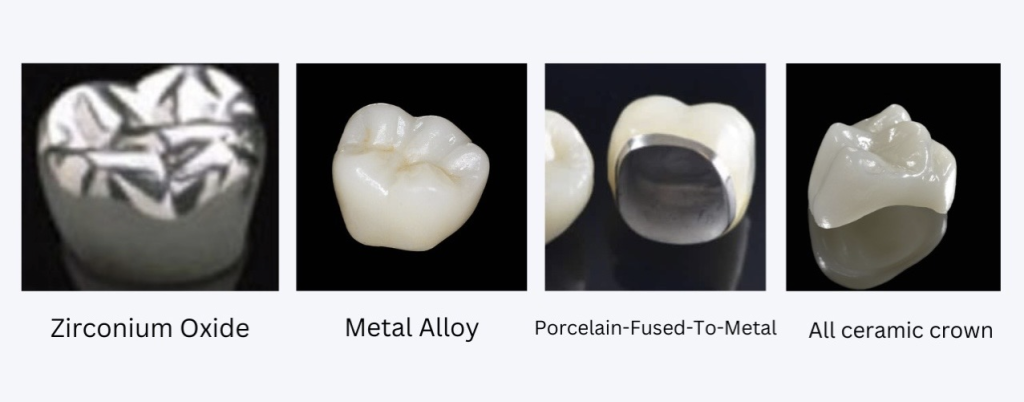

Material used for the crowns & bridges and Types of dental crowns

Numerous dental crown options are available, each tailored to individual preferences and specific oral health requirements.

Zirconium Oxide Crowns

Zirconium oxide crowns, also known as zirconia crowns, are a type of dental crown made from a strong and durable material called zirconium oxide. Zirconium oxide is a ceramic material known for its excellent strength, biocompatibility, and natural appearance

Metal Alloy

Metal alloy, also known as metal-ceramic crowns or porcelain-fused-to-metal (PFM) crowns, are a type of dental crown that combines the strength of metal with the aesthetic appearance of porcelain.

Porcelain-fused-to-metal

Porcelain-fused-to-metal (PFM) crowns are a popular type of dental crown that combines the strength of metal with the aesthetic appearance of porcelain.

All-ceramic materials

All-ceramic materials, also known as all-porcelain or ceramic crowns, are a type of dental crown made entirely from ceramic materials without the use of any metal components. These crowns are valued for their natural appearance, biocompatibility, and aesthetic appeal. Material: All-ceramic crowns are made from various types of dental ceramics, such as lithium disilicate, zirconia, or alumina. These ceramics are known for their excellent aesthetic properties, including translucency and color-matching capabilities.

While not as strong as metal-based crowns, modern ceramic materials used in all-ceramic crowns have improved significantly in terms of strength and durability. Advanced ceramics like zirconia provide excellent strength and can withstand normal biting and chewing forces.

Leucite Reinforced Pressable Porcelain Crowns

Leucite Reinforced Pressable Porcelain Crowns, known as IPS Empress crowns, were first introduced 15 years ago. These crowns exhibit a flexural strength of 160MPa, making them highly durable while providing exceptional aesthetic results. This system enables clinicians to achieve restorations that closely mimic natural teeth. By using a die-shade guide, the shade of the tooth preparation can be determined, aiding in the selection of the appropriate tooth shade. This crucial information allows the technician to choose the correct ingot for pressing the crown. The high translucency of IPS Empress crowns facilitates the transmission of shade from neighboring teeth, ensuring precise shade matching even in challenging cases.

Lithium Disilicate Porcelain Crowns

Lithium Disilicate Porcelain Crowns, known as IPS e.max crowns, are crafted from biocompatible lithium disilicate ceramic glass ingots. These crowns exhibit exceptional resistance to fracturing, boasting a flexural strength of 400MPa, which is three times stronger than Empress crowns. They can be either pressed or milled to ensure a precise fit and optimal functionality. IPS e.max enables the creation of full-contour restorations, or the layering of enamel porcelain using IPS e.max Ceram, a comprehensive layering ceramic renowned for its ability to achieve highly aesthetic outcomes.

Solid or Monolithic Zirconia crowns

Solid or Monolithic Zirconia crowns are highly recommended for posterior restorations due to their exceptional strength, boasting a flexural strength of 1200MPa. These crowns are typically fabricated using CAD/CAM technology, ensuring precise marginal fit and virtually indestructible durability. While early versions of monolithic zirconia crowns often had high value, advancements in shade technology have significantly improved their ability to closely match adjacent natural dentition. Effect shades can be utilized to characterize the occlusal surface of the crown, and the latest monolithic zirconia crowns offer natural translucency and opalescence. Their smooth surface and outstanding durability make them a suitable choice for individuals with bruxism. Additionally, if any occlusal adjustments are required during fitting, monolithic zirconia can be easily polished using conventional low-speed polishing materials for porcelains. As the shade remains consistent throughout the crown, there is no risk of the opaque layer showing through, which is often a concern when adjusting conventional porcelain-fused-to-metal crowns.

Zirconia

High Translucent Zirconia is an excellent choice for anterior crowns, although it can also be used for posterior crowns. This material exhibits a lifelike translucency and possesses a flexural strength ranging from 590 to 720 MPA. In addition to its natural aesthetic appeal, high translucent zirconia is highly biocompatible and promotes a healthy response from the surrounding tissues. When placed in the oral cavity, this type of zirconia allows the color of adjacent teeth to shine through, resulting in seamless blending with the natural dentition. High translucent zirconia can be used in either monolithic restorations or layered restorations, providing versatility in treatment options. The exceptional translucency of this material is achieved through a meticulous processing method that minimizes the presence of impurities and structural defects, ensuring optimal light transmission. By reducing the impact of impurities and defects, the risk of light absorption or scattering is significantly mitigated, allowing for the desired lifelike appearance of the restoration.

It’s important to consult with a dentist to determine the most suitable type of crown for your specific dental needs and aesthetic preferences.

How dental crowns are made step

It’s important to note that the specific steps and techniques may vary depending on the type of crown and the dentist’s preferred approach.

Dental crown fabrication involves several essential steps. Here is a general outline of the process:

- Consultation and Examination: Your dentist will assess your teeth and determine if a dental crown is necessary.

- Tooth Preparation: If a crown is recommended, the dentist will carefully reshape the tooth by removing a portion of its outer structure to create space for the crown.

- Impression Taking: An impression of the prepared tooth and adjacent teeth is taken using dental putty or a digital scanner. This impression serves as a model for creating the crown.

- Shade Selection: The dentist will match the shade of the crown to your natural teeth, ensuring a seamless and aesthetically pleasing result.

- Temporary Crown Placement: While the permanent crown is being fabricated, a temporary crown is placed to protect the prepared tooth.

- Crown Fabrication: Using the impression, a dental laboratory technician or CAD/CAM system crafts the permanent crown. The choice of crown material, such as porcelain, metal, or ceramic, determines the specific fabrication process.

- Crown Fitting: Once the permanent crown is ready, the dentist removes the temporary crown and assesses the fit, shape, and color of the new crown. Adjustments are made if needed to ensure proper fit and bite alignment.

- Cementation: After confirming the crown’s fit and aesthetics, it is permanently cemented onto the prepared tooth using dental cement. Any excess cement is removed, and the bite is evaluated for proper alignment.

It’s important to note that specific steps and techniques may vary depending on the type of crown and the dentist’s approach.